A wooden floor protects the floor of the car and provides a stable and non-slip surface to transport cargo. The anti-slip layer, together with the lashing eyes, ensures that the load does not slide.

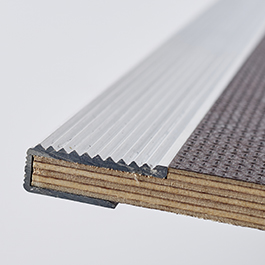

For the floors, we use high-quality plywood sheet materials, made from European birch wood. The top layer of the floor is provided with a wear-resistant and oil- and water-resistant anti-slip layer. Floor plates are manufactured as much as possible from one piece by us. This is possible up to a length of 3.76 m. Where a floor consists of 2 parts, it is provided with a stair connection so that it can be mounted seamlessly. The floor can also be glued and sealed all around. This makes the floor liquid-tight and easy to keep clean.

The thickness of the floor is 9 or 12mm. Both are available in brown and the 9mm also in gray. If desired, we adjust the color of the wall covering to the choice of the floor plate.

New in the range is a lightweight floor plate. By using a lighter type of wood, with a high-quality top layer, up to 40% weight can be saved. For use where high payload is important, but also, for example, in electric commercial vehicles.

“The difference is in the details,” we say at Motexion. The finishing of floor plates is of a high level. Apart from the fact that the floor plates are fitted with deepened lashing eyes as standard, the floor is milled at an angle when boarding, so that the load does not hit the side of the floor. In addition, the edges are painted in the color of the floor for a nice finish. Optionally, it is possible to finish the entrance on sliding and / or rear doors with an aluminum protective strip.

We are also happy to respond to customer specific wishes. For example, by milling aircraft rails in the floor, preparing installation fittings, or working with other materials.

Download our online brochure right away.